Introduction

Coming across the TOYOTA brand and their way of doing business impressed me so much that I had to stay a little bit longer on this subject and explore everything I could, regarding this, really unique and representative approach towards the economy, that continues to develop even now.

First of all, I would have to introduce you several terms that are going to be used in the article:

- TPS – TOYOTA production system. This is the core philosophy of production and development in TOYOTA , recognized as one of the most efficient approaches to production and systems. We will discover more on this topic later on. (More about this term on the following link).

- JIT – Just in time production. Philosophy developed by one of the most famous Toyota directors, which represents tendency to create such a production that would not need storage space if it is not really needed. Also, more on that topic, later on. ( More about this term on the following link).

- MUDA – The waste. One of the most important points of Toyota production is the elimination of (unnecessary) waste production by the philosophy proposed in:

- Lean production – Production strategy that comes along with the JIT and MUDA. Focal point is eliminating unnecessary work and half-product(s) that doesn’t directly create added value for the end customer.

All these terms are mainly with the focus on efficiency, introduced to the world by Toyota think tanks, which are, again, mainly responsible for creating this automotive monster, or, in other words, the biggest automotive manufacturer in the world. Many companies tried to replicate TPS because it represents steady but secure and sustainable growth in economical way.

One of the most important values that TOYOTA respects, is the value of information and knowledge sharing. We will see how the production is divided in wide network of suppliers, how they are stuck together, and which network concepts we could recognize in the production process. Knowing that our key brand here is global company that covers all continents (except Antarctica) we could recognize pretty much all concepts of production and knowledge sharing.

At the end of the introduction, I have to point out that the sustainability is within the core principles of the TOYOTA business.

TPS

The main reason I made this as a separate subheading is that TPS is viewed as a philosophy that is spread through the whole network of TOYOTA production. That means horizontal and vertical diffusion of the term. Both within the company AND the suppliers or sub-contractors.

Figure 1 – TPS and TOYOTA values

I would like to try to explain in more details key terms here, relevant for the continuing of this presentation.

JIT

Just-in-time production relies on finely tuned processes in the assembly sequence using only the quantities of items required, only when they are needed. Thus, reducing the unnecessary storage space, and in the same time trying to level the production which brings even more efficiency in the process.

Imagine a process designed to produce six different types of product, where the total weekly demand for the range of products varies up and down by 25%, and the daily mix of product types is continuously changing. A planning challenge, but also a typical scenario in many types of business in which the process (manufacturing or otherwise) has to continuously respond to demand. TPS has responded to this reality of life by developing an approach that can meet the challenge in an efficient, cost-effective way, which is JIT.

Elimination of Waste – MUDA

The driving force of the Toyota Production system is the elimination of waste aimed at ever improving quality, cost, productivity, safety and morale. The result is greater satisfaction for major constituents: customers, employees and investors.

Continuous improvement focuses on the elimination of seven major types of waste.

1. CORRECTION/SCRAP

2. OVER-PRODUCTION

3. WAITING

4. CONVEYANCE

5. PROCESSING

6. INVENTORY

7. MOTION

The waste is defined as anything that does not add value – includes things that might not normally be considered as waste such as overproduction, holding too great an inventory, the need for rework, and unnecessary movement, processing and waiting.

The production network of Toyota

The “ production network” in TOYOTA is consisted of the group of firms which collaborate to develop and manufacture a motor vehicle. The automaker, Toyota, is the “central” or core firm in the network because:

- Toyota is the only firm with direct ties to every other firm in the network, and

- Toyota coordinates the activities of all firms in the network.

As the central firm, Toyota also has the most to gain from developing learning routines that increase the efficiency of the entire value chain or production network.

Toyota has developed a wide range of organizational routines to enhance “supplier development” and inter-firm learning. Purchasing takes the lead role in coordinating supplier development activities, but all divisions have specific “supplier development” responsibilities. When necessary, these different functions work together to solve problems with suppliers.

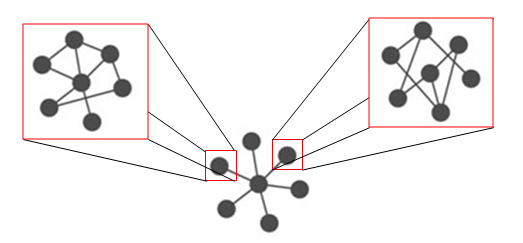

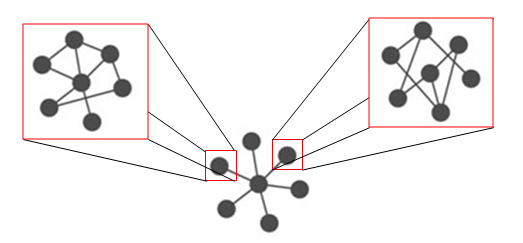

This being said, we can conclude that the TOYOTA network is central based (or star) type of network with the TOYOTA Motor Corporation is in the middle. Further unfolding the network, we could define that other actors are also connected in mutual networks of collaboration which we defined as bridged networks through TOYOTA M.C. (Figure 2.)

Figure 2 – Toyota network as a bridging central type of network

That network is being diffused all around the globe with local and global partners, from which, the most important role play Japanese and US supplier networks.

As we would proceed further with trying to define the concepts of network creating, we could conclude that all three proposed are present.

Concepts of networking

AGGLOMERATION

Agglomeration is mentioned in almost all 7 points of the waste reduction (mentioned before), but mainly in Conveyance where it is defined that material should progress from one cell or position to the next as quickly as possible without stopping at any intermediate storage place.Shipping areas should be close to the end of the process. Work teams and support units should be located close together.

That was why the Supplier Association was created. Toyota’s supplier association (kyohokai) in Japan was established in 1943 to promote “mutual friendship” and the “exchange of technical information” between Toyota and its parts suppliers with three stated “purposes”:

- information exchange between member companies and Toyota,

- mutual development and training among member companies, and

- socializing events.

*(Internal Toyota Document, 1996).

Toyota has created three separate regional associations because it recognizes that for the supplier associations to

achieve their objectives, the suppliers must be in close geographic proximity (e.g., within 3-4 hours by car or train).

INDUSTRIAL COMPLEX

Within their own production system, TOYOTA has created the whole city of interlinked factories, thus creating a huge, industrial complex, called – TOYOTA city, shown on Figure 3. (Click on photo for more info)

Figure 3 – Toyota city

SOCIAL NETWORK

TOYOTA is investing a lot in creating a unique social network between the suppliers, and that is maybe the crucial differentiation point with which TPS is so different from other systems. That is why I will elaborate this in more details.

Developed were bilateral and multilateral knowledge sharing routines with suppliers that were resulting superior inter-organizational or network learning. The unique way to do this is by teaching partners in network that sharing information and know-how is mutually beneficial, thus resulting in constant learning from each other, thus constantly improving the system. As a result, production networks that are particularly effective at transferring know-how are likely to outperform competing networks.

Within these routines, several processes were developed as well, and we will mention some of them :

1. Voluntary Learning Teams (Jishuken)

OMCD (Operations Management Consulting Division) facilitates knowledge sharing across suppliers in a way that is quite unique within the automotive industry (and perhaps within any industry). In 1977 OMCD organized a group of roughly 55-

60 of its key suppliers (providing over 80 percent of its parts in value) into “voluntary study groups” for the purpose of assisting each other with productivity and quality improvements.

The basic idea is to help each other increase productivity in areas of common interest, such as reducing lead times or

inventories. Supplier executives that participate in jishuken activities are typically plant managers, assistant plant managers, and/or section managers (each member company usually has 5-8 people taking part in the activity).

2. Interfirm Employee Transfers (shukko)

In Toyota’s case, shukko is also an important mechanism for transferring knowledge to suppliers.Overall, Toyota transfers approximately 120-130 individuals per year to other firms in the value chain, most of whom go to suppliers.

3. Problem solving teams

Toyota has a process of forming problem solving teams designed to bring knowledge to bear in solving emergent problems within the network. In some cases, Toyota may determine that the relevant knowledge resides within a competitor of the supplier. In this case, Toyota will attempt to orchestrate a supplier-to-supplier knowledge transfer.. According to Toyota executives, upgrading the skills of the inferior supplier not only improves the quality of the weaker supplier but also stimulates long-term competition.

4. Performance Feedback and Monitoring Processes

Finally, by providing frequent performance feedback to suppliers and by monitoring whether or 18 not suppliers implement new knowledge/technology, Toyota pushes suppliers to learn and implement new knowledge.

Concluding this paragraph, I would like to stress out the evolution of this system. In the beginning it was strange that suppliers (that are often in competitive relation among each other) share information and the know-how. However, after a lot of time and other resources invested in this idea (especially in US), the result was that suppliers are pushed to develop faster, thus creating more competitive surrounding for the others, which closes the loop of striving for better and more perfected products and processes.

Non local actors

We have concluded that as a global company, it is a necessity to have global partners. Maybe the most important ones are positioned in US, where TOYOTA tried (and succeeded) to implement, in that time totally unfamiliar system – TPS.

Now, Toyota is preforming with the crucial suppliers, coordinating companies, manufacturing companies, etc, depicted on Figures 4 and 5 (click on the figures for more details).

Figure 4 – Overseas coordinating and manufacturing companies

Figure 5 – Overseas and liaison offices

Toyota started its U.S. supplier association (Bluegrass Automotive Manufacturers Association, or BAMA) in 1989 with only 13 suppliers. Involvement was voluntary and most of the initial members were U.S. suppliers and Japanese transplants located in close proximity to the Georgetown, Kentucky plant. The initial objective was to provide a monthly forum for haring information with suppliers and for eliciting supplier feedback.

Nielsen, assistant general manager for purchasing planning commented on a new, strange system introduced by TOYOTA:

“We really didn’t know if this would work in the U.S. Getting suppliers to talk to each other was a key element of the program. Before BAMA, it was not very natural for supplier executives to talk and share information. It was uncomfortable. Over the years that has changed significantly as suppliers have built relationships at senior levels” (Interview, November 17, 1997).

This message is echoed by the plant manager of a Toyota supplier.

“Before BAMA, we really didn’t know or share information with executives at other suppliers. And we just didn’t think about calling them up or visiting. It just didn’t happen. BAMA has helped us to get to know each other and now it feels a lot more comfortable calling up another supplier for information or even visiting their plants” (Interview, November 18, 1997).

The general assembly, top management meetings, and executive meetings are designed to allow for high-level communication within the network with regard to production plans, policies, market trends, etc. Thus, these meetings primarily facilitate information sharing among members. More frequent interaction occurs within the divisional committees and topic committees (cost, quality, safety, etc.) where members engage in both information and know-how sharing. Divisional committees are comprised of suppliers who join the meetings because of the nature of the parts they produce or the production processes they employ. For example, division committee 2 is comprised of suppliers who primarily supply parts to the powertrain (engine, transmission, etc). of Toyota vehicles. This allows Toyota and its members to share knowledge with others that are making parts which interface with each other. It also facilitates knowledge sharing among members using similar production processes. This method of grouping suppliers ensures that the information and know-how shared is relevant to the supplier member.

The topic committees on cost, quality, safety, and general affairs are designed to facilitate knowledge sharing on topics that are critical to all members in the network.The PR-Sports committee is created with the goal to create a positive social network among all actors within the network.

The quality committee, established in 1961, engages in a number of activities designed to improve

the quality capabilities of members of the network. The “regular committee” picks a theme for the year and meets six times each year to share knowledge with regard to that particular theme. These themes are selected by suppliers (with Toyota’s input) in areas believed to be important and relevant to a large number of members in the network. In addition to the “regular committee” meetings, the quality committee also sponsors “basic quality training,” “excellent plant tours,” and an annual “quality management conference”.

In summary, the supplier association’s primary objective is to develop ties among members and transfer explicit knowledge through multi-lateral knowledge transfers. The subcommittees are designed to facilitate the transfer of both explicit and tacit knowledge.

Operations Management Consulting Division (OMCD)

The purpose of OMCD is to maintain a group of internal consultants with high levels of expertise in operations to assist in solving operational problems both at Toyota and at Toyota’s suppliers.These individuals are assigned the task of assisting plants achieve productivity improvements, inventory reductions, and quality improvements.

OMCD facilitates knowledge sharing by providing direct assistance to suppliers, who must request OMCD’S assistance (usually through the purchasing division). This typically involves sending a team of consultants to the supplier for a period of time ranging from 1 day to many months, depending on the nature of the problem.

The U.S. version of OMCD is called the Toyota Supplier Support Center (TSSC).

Toyota does not charge fees for its assistance but does demand that participating suppliers be willing to let Toyota bring other companies to see their operations when the project is completed.This allows Toyota to:

- develop some “showcase suppliers” that have successfully implemented the TPS; this provides a valuable learning laboratory for other suppliers attempting to improve their operations, and

- start the process of getting suppliers their operations to one another.

It is worth noting that Toyota does not ask for immediate price decreases or a portion of the savings from

the improvements. However, suppliers claim that they often pass on some of the savings due to a feeling

of obligation.

Closing material loops

One of the main goals of TPS is destroying waste as the term, and working in sustainable way. That means that with knowledge transfer described, Toyota should be capable of creating such a network that could eventually close the loop of production in several areas of it.

Currently, I cannot find the example of such a production within the TOYOTA network, but I believe that it is the way of future direction of TPS. Baring in mind that the JIT and Lean production both promote continuous flow over the batch processing can lead us to conclusion that TOYOTA way is striving towards the most efficient production as it can manage or create.

Conclusion

Working with Toyota as a supplier is not easy because Toyota is extremely demanding and expects continuous improvement (learning). But Toyota’s efforts to assist suppliers and to encourage them to improve have resulted in a supplier base that is the most productive in the industry,creating networks of communication, information sharing and collaboration.

In summary, Toyota has created a number of complex routines designed to store and diffuse knowledge within the network and facilitate both bilateral and multi-lateral transfers of both explicit and tacit knowledge, thus evidently improving the efficiency of production. Furthermore, network members know where to find different types of knowledge so it reduces their search costs.

Toyota’s ability to effectively create and manage knowledge sharing processes within its production network at least partially explains the relative productivity advantages enjoyed by Toyota and its suppliers (Lieberman et al, 1997; Dyer, 1996). As Toyota’s international purchasing chief, Michio Tanaka, observed, Toyota is simply better at “knowing how to implement TPS in specific factories and contexts.” Maybe… the most important know-how to be implemented in the network…

Resources:

- http://dspace.mit.edu/bitstream/handle/1721.1/1441/147b.pdf

- Wikipedia, under tags: JIT , Toyota , Lean production ,

- http://www.artoflean.com/files/Basic_TPS_Handbook_v1.pdf

- http://www.toyota-forklifts.eu/SiteCollectionDocuments/PDF%20files/Toyota%20Production%20System%20Brochure.pdf